Compounding of fluorinated elastomers

Welcome to our production facility: here, advanced technologies, dedicated processing lines, and state-of-the-art control systems convert formulations into high-performance FKM, FFKM, and FVMQ compounds, ensuring superior quality and reliability for the most demanding applications.

FKM compounds production

Used for applications requiring high chemical, thermal, and weather resistance

FFKM compounds production

Suitable for extreme chemical and thermal environments in the chemical, oil and gas, and aerospace sectors

FVMQ compounds production

Suitable for fuels, mineral oils, and hydrocarbons. High elasticity even at very low temperatures

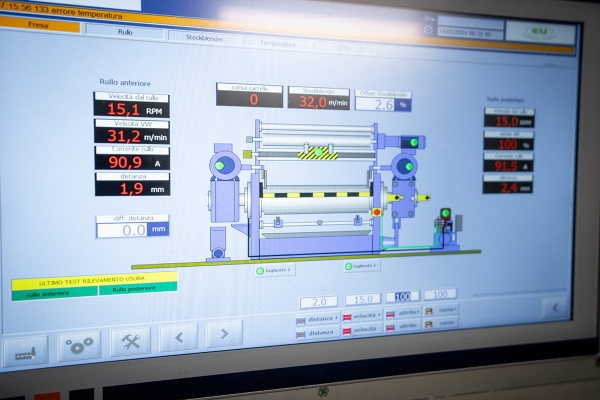

Production Lines

Versatile production lines equipped for every need: from large supplies to samples, always with guaranteed quality control.

Line 1

HF line with a 90-liter Bambury, a 2100 mm open mixer, and a 1500 mm open mixer.

Packaging in:

- continuous strips

- sheets

- reels

Line 2

Line with a 35-liter Bambury and a 1500 mm open mixer, tank with release agent and batch-off with drying.

Packaging in:

- continuous strips

- sheets

- reels

Line 3

Line with a 5-liter Bambury, laboratory mixer, and small samples of 5-7 kg.

Filter die

Colmec filter die with release agent tank and batch-off for drying.

Optimized weighing and dosing system

Since our founding, we have focused on technological innovation to offer our customers better products and a more comprehensive service.

The weighing and dosing system is designed, thanks to an innovative conveyor system, to reduce human intervention so as to achieve optimized raw material dosing.

- 2 Independent Production Lines

- 1 Closed Mixer

- 2 Open Mixers

- 1 HF Line with Dynamic Pressure Management

- 1 Batch-off Line

- 0,11mm Maximum Diameter for Optional In-line Filtration Process

Quality

Quality guides every stage of our work: selected raw materials, rigorous controls, and thorough testing ensure high-performance, reliable compounds that meet the highest standards.

Quality

Every Batch Under Control: Visit Our Quality Laboratory

A network at your service to ensure quality, reliability, and innovation at every stage of the production process.

Discover the Network