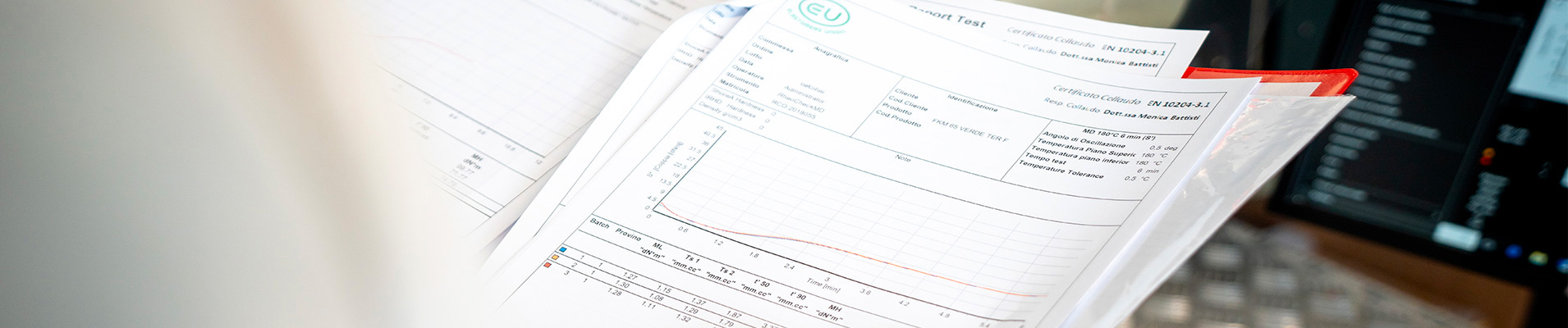

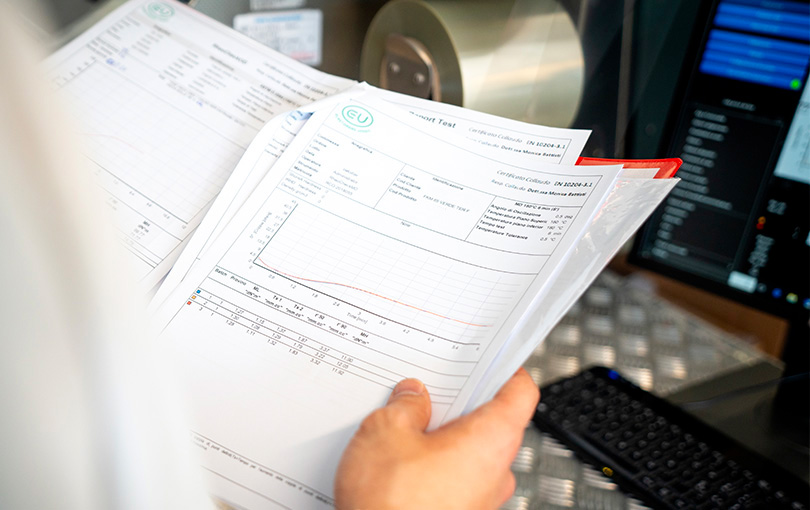

Quality: Outgoing Batch Control

Our laboratory tests a sample of each batch produced with standard analyses, ensuring customers receive compounds that meet their specifications.

Standard Analysis

Each batch is subjected to standard analyses to ensure consistency and compliance of FKM, FFKM, and FVMQ compounds.

From hardness to viscosity, including vulcanization time and density, every parameter is monitored to ensure quality, traceability, and reliable performance over time.

- Vulcanization

- Density

- Hardness

Specific Analyses

For critical applications or specific technical needs, we perform specific, customized analyses designed to validate compounds in extreme conditions or highly aggressive environments. Each test is designed to meet advanced functional and regulatory requirements.

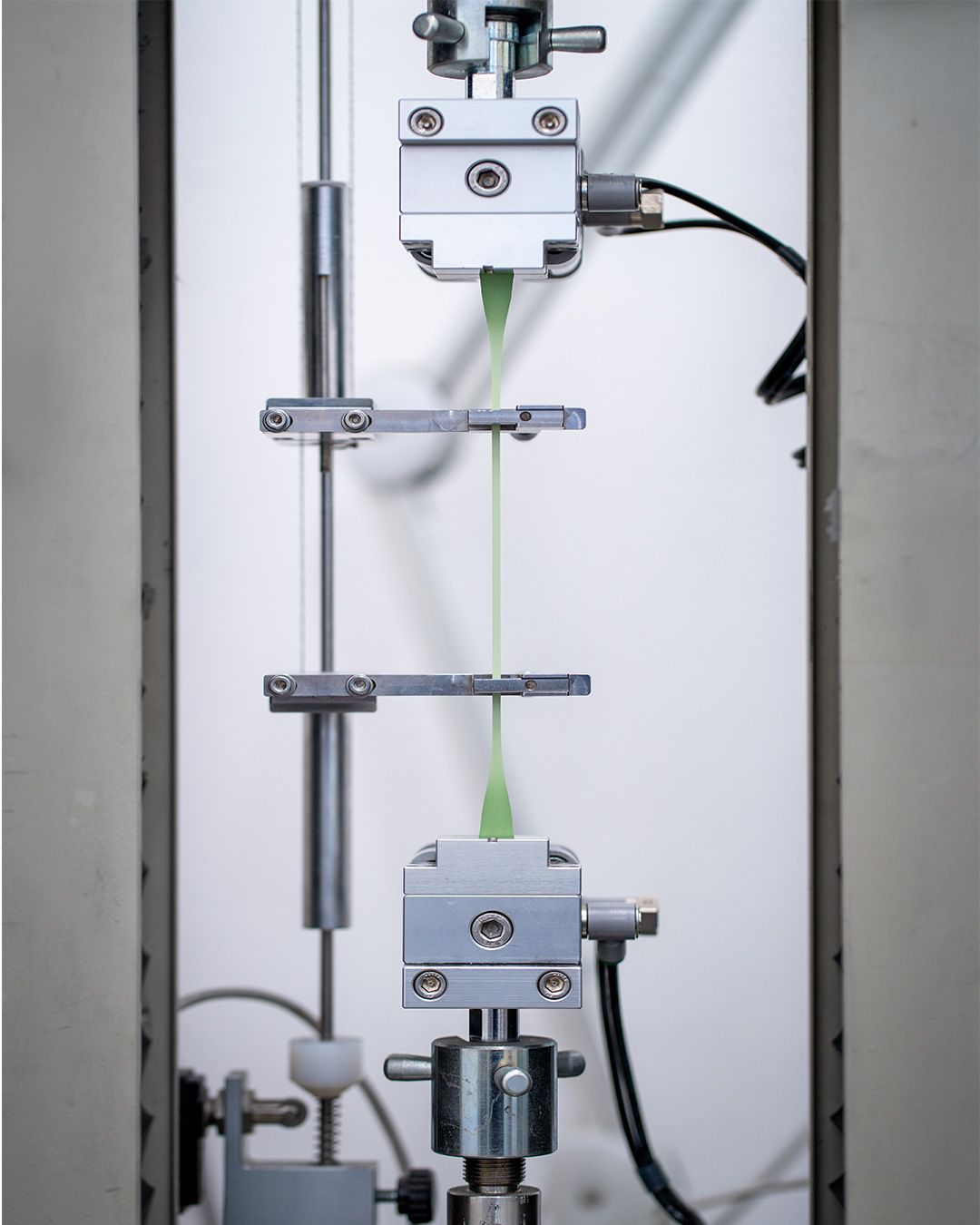

- Physical and mechanical properties

- Resistance to thermal aging

- Resistance to chemical aging

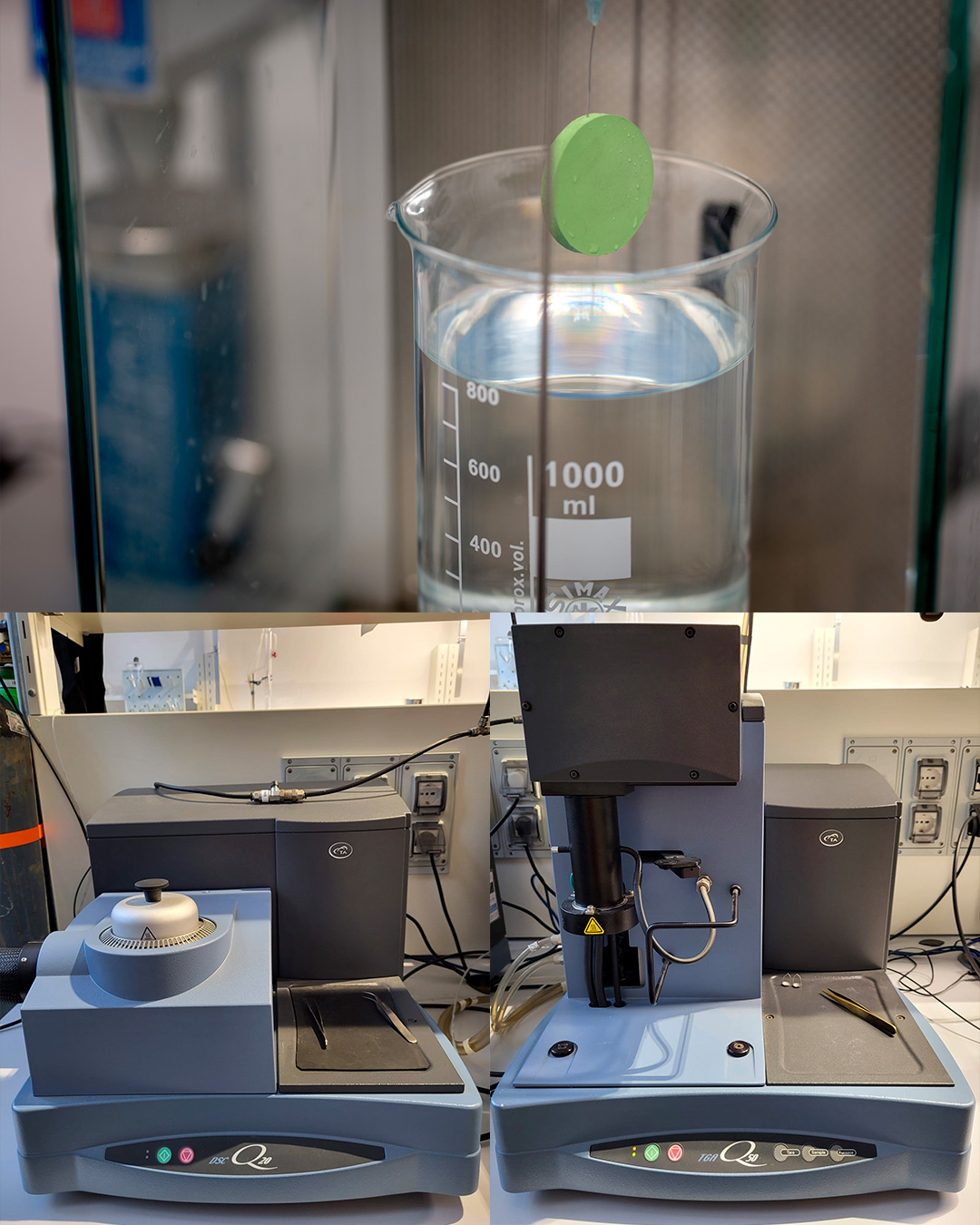

- DSC differential scanning calorimetry

- GPC gel permeating chromatography

- TGA thermo gravimetric analysis

- E FT-IR Fourier transform infra red spectroscopy with ATR modulus

ISO 9001

Quality Management System (QMS) Certification

ISO 14001

Environmental Management System (EMS) Certification

FKM, FFKM, and FVMQ production: control at every stage

We produce custom FKM, FFKM, and FVMQ compounds, controlling every stage: development, production, packaging, and after-sales support.

Production

From polymer to compound: join our production team

A network at your service to ensure quality, reliability, and innovation at every stage of the production process.

Discover the Network