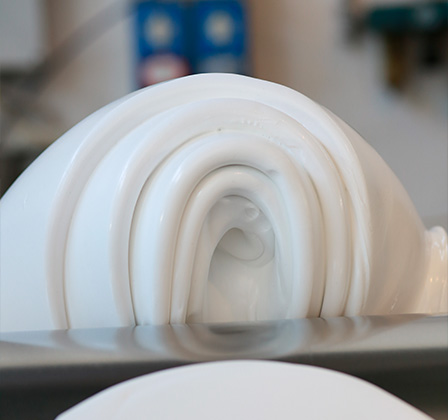

FVMQ Compounds

FVMQ (fluorosilicone) compounds are the ideal solution for applications requiring low-temperature elasticity and resistance to fuels and oils. Thanks to their unique chemical structure, they combine the flexibility typical of silicones with the chemical resistance of fluoroelastomers.

In this page, we explore the characteristics, applications, and performance of our FVMQ formulations.

Main Applications of Fluorosilicone Compounds

FVMQ compounds are used in applications requiring both resistance to fuels and oils and elastic stability at low temperatures. Their main areas of use include:

- Automotive and transportation: gaskets for engines, carburetors, and fuel systems.

- Aerospace: components subject to temperature fluctuations and aggressive fuels.

- Industry: seals exposed to hydrocarbons, mineral oils, and solvents.

- Electronics and sensors: protection in chemically aggressive environments and extreme temperatures.

FVMQ Material Properties

Fluorosilicone is an elastomer obtained by modifying traditional silicone with fluorinated groups, which significantly improve its chemical resistance without compromising flexibility.

Its main characteristics include:

- Excellent resistance to fuels, mineral oils, and aromatic solvents

- Excellent flexibility even at very low temperatures (down to -60°C)

- Long-term dimensional stability

- Good resistance to ozone and atmospheric agents

- Stable electrical insulation under critical conditions

- Low permeability to gases and vapors

- Consistent elastic behavior over a wide temperature range

Fluorosilicone (FVMQ) Service Temperature

FVMQ compounds maintain flexibility and elasticity from -60°C to +180°C, with good performance even under repeated thermal cycles. They are therefore suitable for use in both cold environments and dynamic conditions.

Chemical Resistance of Fluorosilicone Rubber

One of the distinguishing features of FVMQ is its combined resistance to fuels, oils, and solvents that typically degrade traditional silicones. This makes it ideal for mixed-environment applications, such as engines and fuel systems.

A network at your service to ensure quality, reliability, and innovation at every stage of the production process.

Discover the Network